The Multi-Function Dosing Station for Control and Maintenance of pH (hydrogen ion concentration), Cl (free chlorine), and Rx (oxidation-reduction potential) of swimming pool water.

For public and private pools of volume from 1 to 1000 cubic meters.

FUNCTIONALITY:

Dosing and control;

Control of 2 filtering pumps with smooth start and stop;

Control of the pool heating circuit;

Control of the water level in the pool;

Control of 2 automatic reverse chlorination cycles;

Control of the ultraviolet lamp;

Built-in remote access via Bluetooth and Wi-Fi.

DOSING AND CONTROL:

The high-precision adaptive logic algorithm for dosing any type of chemistry allows achieving the best parameters, maintaining the required concentration with maximum precision.

Automatic cleaning of the free chlorine amperometric sensor. By applying voltage to the sensor electrode, the station performs a cleaning of the gold base from oxidations in an automatic mode. This function allows significantly extending the sensor's lifespan and minimizing the need for servicing.

Three galvanically separated inputs allow significantly increasing the accuracy of pH, Cl, and Rx measurements, and, accordingly, subsequent dosing control of chemical agents.

Control of the state of the sensors pH, Cl, and Rx. The station analyzes the readings from the sensor electrodes at each cycle of dosing and sends a notification if the dosing is not responding, prompting a check of the sensor state and subsequent calibration.

Two membrane dosing pumps with a performance of 10 L/hr and two peristaltic dosing pumps with a performance of 2.2 L/hr (optional 1.5 L/hr) are capable of dosing any type of chemistry for swimming pools. (default: 1 - pH, 2 - Cl, 3 - Floc, 4 - Alg).

The ability to connect an unlimited number of duplicate dosing pumps with a performance of up to 10 L/hr.

Exclusion of simultaneous dosing of agents Cl and pH, as their mixing leads to the formation of toxic chlorine gas in a gas form.

Built-in overdose protection - this adjustable setting is the maximum allowable daily dose of chemical agents, needed to achieve the required concentration in the pool water. The daily dose is set for each type of chemistry. If the upper limit is reached, the station stops the dosing cycle until the next day, when the measuring sensor is re-calibrated, thereby excluding the instantaneous daily limit.

Control of the chemical level in the canister. The chemical level sensor prevents water shortage in the dosing line, which excludes crystallization of chlorine. The pump stops at the right time, watching the level of chemistry in the canister (Acon ACON entry nodes are included in the package).

Control of the flow. The station includes a flow meter sensor.

Dosing, measurements, and event logs. The station maintains logs of the use of chemical agents, values of pH, Cl, Rx, and temperature, and a log of events, which records emergency situations and daily reporting on dosing each type of chemistry.

FILTERING CONTROL:

The smooth start and stop of 2-2 filtering pump units with a power of up to 2.2kW, 220V, each. This allows during the start to keep the parameters of the motor in safe limits, which reduces the likelihood of motor windings overheating and eliminates vibrations in the drive mechanism, as well as the risk of hydraulic shocks in the pipes and valves at the start and stop.

In the settings, 4 loading modes are set:

- Small - 3 hours of work, 5 hours of pause;

- Medium - 5 hours of work, 3 hours of pause;

- Large - 7 hours of work, 1 hour of pause;

- Public - 24-hour operation mode;

The automatic setting of the current consumption of the filtering pump unit is carried out using the calibration of the pump in the control panel menu.

Built-in protections against overloading and "dry run" at the current consumption guarantee the long-lasting and reliable operation of the pumps.

The station has 3 timeout settings for the pump restart, in case of an emergency situation.

POOL HEATING CONTROL:

The temperature of the pool water is monitored using a temperature sensor (supplied with the product) and the necessary actions are taken to maintain the required temperature using the heating coil (valves are supplied separately).

WATER LEVEL CONTROL:

Water level control in the pool - when 5-electrode amperometric sensors are connected.

Water level control in the pool - when two submersible, conductometric or porous level sensors are connected.

The station maintains the required water level by controlling the magnetic valve (sensors can be purchased separately).

Wide range of settings:

Averaging regulation: from 1 to 60 seconds.

Dosing duration: from 1 to 90 minutes;

Pause duration between dosings: from 1 to 10 hours.

Allows using the system for different types of water level oscillations.

Adaptation of the dosing for low-performance wells and boreholes.

AUTOMATIC REVERSE CHLORINATION CONTROL:

The station controls the automatic reverse chlorination filter AUTOCLEAN S-Light, fully automating this process.

In the settings, the parameters for the chlorination, de-clarification, and purging cycles are set:

Duration of the chlorination, de-clarification, and purging cycles;

Weekly schedule with the possibility of setting up to 2 chlorinations per day;

Choice of operating mode of the filtering pump during the chlorination period;

Upper limit of the pressure at which a forced reverse chlorination is performed (the pressure sensor is purchased separately).

ULTRAVIOLET LAMP CONTROL:

The station turns on and off the ultraviolet lamp during the operation of the filtering pump.

INTERFACE:

A matrix display with an intuitive interface in both Russian and English languages. 6 buttons for controlling the menu.

Built-in Wi-Fi and Bluetooth modules. Remote control is carried out via mobile applications ACON WEB CONTROL and ACON Bluetooth CONTROL.

The access to the application is divided into 3 levels:

- Work. A user-specific section with the ability to monitor values and changes in them, the boundaries of which are set in the service section. It also allows you to change the pool loading mode.

- Settings. A section for service personnel with the ability to monitor statistics and change the modes of filtering, reverse chlorination, and dosing.

- Service. A service section with the ability to change all the functions of the dosing station by Bluetooth. In the WEB version, some functionalities are not available because some settings such as sensor calibration or changing the assignment of dosing pumps require physical presence on the object.

By default, the passwords for the settings and service sections are set. This division allows access according to the competence of the employee or user.

Notifications by E-mail. The station itself forms a message and sends it to the specified email addresses in the settings. This feature allows for immediate reaction to problems in the swimming pool, which helps to prevent potentially dangerous situations before they become critical. In the settings, up to 3 email addresses can be set, to which emails will be sent.

RS-485 interface for connection to "Smart Home" systems.

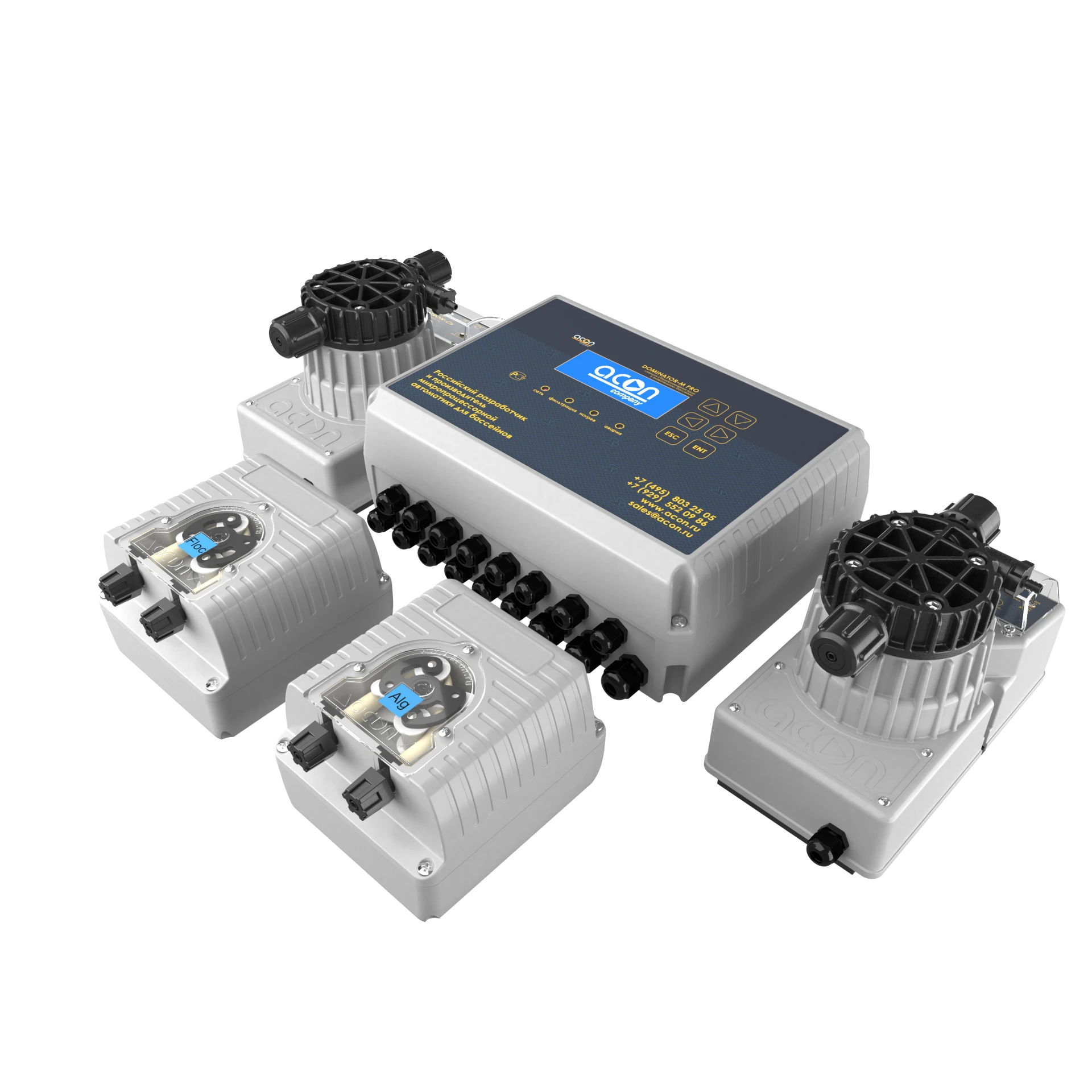

Assembly DOMINATOR-M PRO

- Control block DOMINATOR-M PRO - 1pc;

- Membrane pump DOZATRON - 2pc;

- Peristaltic pump ACON PRM-2 2.2 L/hr - 2pc;

- Dosing pump assembly (inlet and outlet with valves) ACON - 2pc:

- PVC tube 4×6mm (2m) - 2pc;

- Inlet valve elongated 1/2" NR ACON - 1pc;

- Chemical agent dispensing valve 1/2" NR ACON - 1pc.

- Membrane dosing pump assembly (inlet and outlet with valves) ACON - 2pc:

- PVC tube 4×6mm (3m) - 1pc;

- PVC tube 4×6mm (2m) - 1pc;

- Inlet valve elongated 1/2" NR ACON - 1pc.

- Chemical agent dispensing node on a hard stand with a level sensor ACON (PVC stand 0.5m, cable 2m) - 2pc;

- pH electrode 12mm with cable 2m - 1pc;

- Rx electrode 12mm with cable 2m - 1pc;

- Buffer calibration solutions set - 1pc:

- pH 7 - 1pc;

- pH 9 - 1pc;

- Rx 650 - 1pc.

- Free chlorine amperometric sensor FCL - 1pc;

- Flow sensor perforated 1/2" NR - 1pc;

- PVC tube 10×14 mm (5m) - 1pc;

- Sample cell with flow regulator PRO in set (t,2 holding electrodes, 2 fitting,1load.) - 1pc;

- PVC glue welding 1/2" WR-D50/63 - 6pc;

- PVC ball valve 1/2" WR-1/2" NP - 2pc;

- Fitting 1/2" NR-tube D14mm - 4pc;

- Sample collection set - 1pc:

- PVC triangle 1/2" WR - 1pc;

- Fitting 1/2" NR-tube D14mm - 1pc;

- PVC ball valve 1/2" WR-1/2" NP - 1pc;

- Rx/pH holding electrode 1/2" NR - 1pc.

- Pooltester colorimetric Pooltester Cl/pH (0.1-3.0mg/l and 6.8-8.2 units pH) - 1pc;

- Filter for pouring 1/2" WR - 1pc;

- PVC-PVC wire 3×0,75 - 1pc;

- Fasteners set - 1pc:

- Dubel 6*40 - 20pc;

- Screw 4,0*35 - 15pc;

- Screw 4,0*70 - 5pc.

- Instruction - 1pc;

- Warranty certificate - 1pc;

Electrical parameters

Power supply voltage

220В ± 10%

Power frequency

50 Hz

Protection class against electric shock

Class I

Maximum power consumption, not including connected load

50 Wt

Number of operation modes

2 units

Backwash cycle time

3 sec

Protection class

IP56

Dimensions and weight

Dimensions of the control panel

263 х 194 х 100 mm

Weight of the control panel

1 kg

Dosing

Number of metering pumps

4 units

Dosing pump type

Membrane Peristaltic

Maximum capacity of the peristaltic metering pump, at a back pressure of 0.7 bar

1,5 and 2,2 l/h

Maximum back pressure for peristaltic metering pump

1,3 bar

Peristaltic metering pump tube material

Santoprene

Suction and pressure tube material

SOFT PVC

Suction and pressure tube size

4 х 6 mm

Maximum suction tube length of the metering pump

2 m

Maximum dispense pump discharge tube length

2 m

Maximum pumped liquid temperature

+40 С°

Maximum capacity of diaphragm metering pumps, at 1.5 bar back pressure

7,5 or 10 l/h

Operating back pressure for diaphragm metering pumps

1,5 bar

Maximum back pressure for diaphragm metering pumps

5 bar

Diaphragm material for diaphragm metering pumps

PTFE

Diaphragm metering pump valves

Ceramic balls with ring-springs 'Viton'"

Maximum discharge tube length for diaphragm metering pumps

3 m

Operating back pressure for peristaltic metering pumps

0,7 bar

Measurement

Maximum pressure in the sample cell

2 bar

Hydrogen pH measurement range

0,0 – 9,9 units

Measuring range (ORP) Rx

000 – 999 mV

Free chlorine measurement range

0,00 – 9,99 mg/l

Water temperature measuring range

0 – 52 С°

Flow tube material

SOFT PVC

Size of flow tube

10 х 14 mm

Pool volume

Minimum pool volume

1 m3

Maximum pool volume (public)

1000 m3

Maximum pool volume (private)

1000 m3

Environment

Ambient air temperature

+5÷35 С˚

Ambient air humidity

0.75

Filtration

Maximum load current for each filter unit pump

10А (2,2kW)

Maximum load current for UV lamp connection

2А (0,4kW)

Number of filtration pumps to be connected

2 units

Heating

Maximum load current for connection of heating actuators

2А (0,4kW)

Water refill

Maximum load current for connection of the water refilling actuator

2А (0,4kW)

Connection type of level sensors

Conductometric Porcelain (Hercynite)

Adjusting the averaging duration

1 – 60 sec

Adjusting the duration of water refilling

1 – 90 min

Adjusting the pause duration

1 – 10 h

Remote access

Wi-Fi

IEEE 802.11 b/g/n-compliant

Wi-Fi network frequency range

2,4 GHz

Bluetooth LE

Bluetooth 5

Material

Diaphragm metering pump head material

Armlen

Filter cleaning

Pressure setting range

0,5 – 2,0 bar