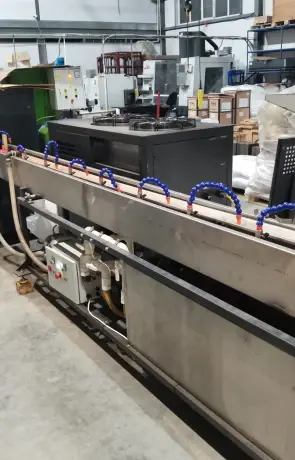

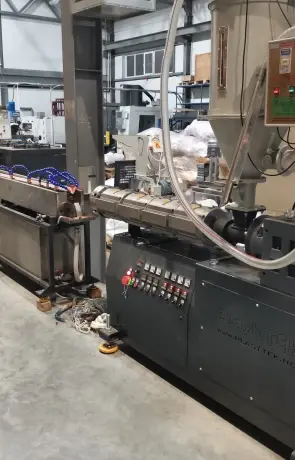

All plastic parts are molded on Haitian's own injection molding machines.

Only high-tech polymers resistant to chemical reagents are used as raw materials. Thanks to its own production of plastic products, ACON has a large stock of finished components and spare parts.

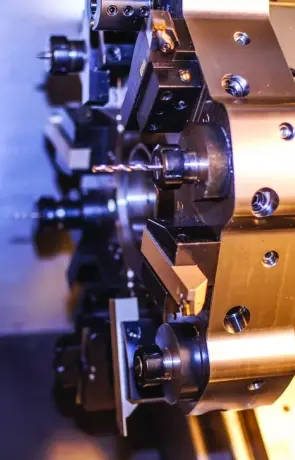

For metal processing we use high-precision milling and turning machines made by HAAS (USA). All metal components in our products are manufactured on our own machines.

ACON can quickly introduce new developments due to the absence of intermediaries like other companies.

Due to the full cycle of production ACON is able to maintain a stock of components for tens of thousands of units of finished equipment, which avoids delays in shipments.

Company goal

-

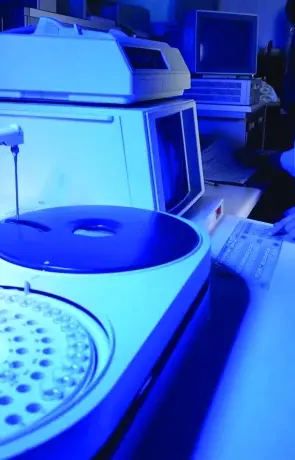

ACON is constantly evolving and finding innovative solutions in the development of its own products as well as the company itself. The company's goal is to provide equipment that guarantees perfect swimming pool water.

Company mission

-

ACON's main mission is to design and manufacture the highest quality electronic control systems for private and public swimming pools. Developing a successful and efficient business, ACON offers customers a wide range of high quality pool equipment at the best price and service level.

Company history

-

The desire to develop and automate production are factors that shaped and characterized ACON as a company back at the beginning of its journey.

Employees

-

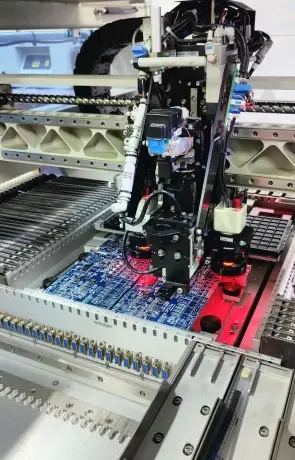

One of the strongest advantages of ACON is a team of highly qualified engineers and programmers engaged in the development of the latest automation systems and continuous improvement of hardware and software.

-

We have a team of more than 30 people who handle large production due to its full automation.

Dealers

-

ACON has a large dealer network, which allows you to buy our equipment in any city in Russia and CIS countries.

-

The main principle in dealer relationships is constant support and no competition for retail sales due to the fact that equipment is sold only through dealers and partners.

-

Regular seminars provide dealers with up-to-date information about the equipment.